多级高压调试注意事项

Attentions in commissioning multistage high pressure pump

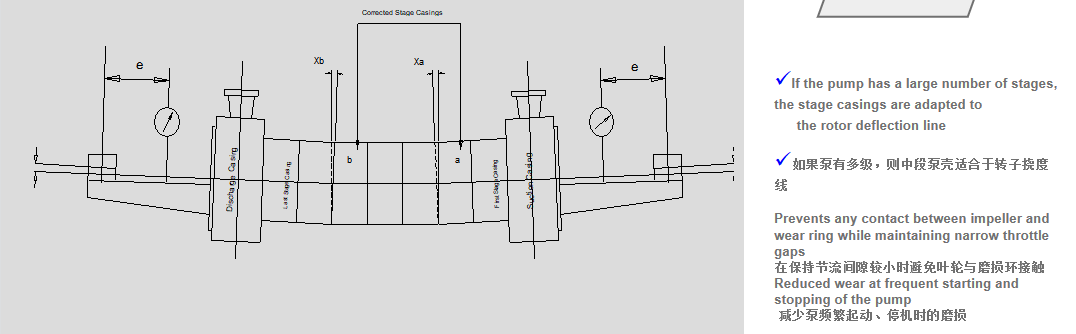

轴向节段式多级高压离心泵,由于扬程高,多使用于锅炉给水系统。对于此类泵的调试,主要需要考虑以下几种情况。

Axial segmental multistage high pressure centrifugal pump is used in boiler water supply system because of its high head. For the debugging of this kind of pump, the main need to consider the following situations.

水泵调试前准备:

Preparation before pump commissioning:

1,入口阀门已经打开,泵体已经注满水。

The inlet valve is open and the pump is filled with water.

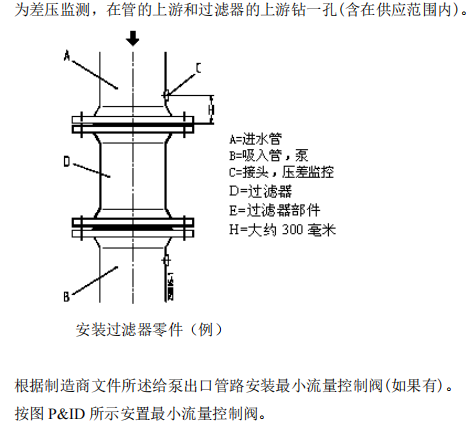

2,由于试车,新管路系统一般有杂质,需要考虑在新泵入口加装滤网,滤网目数视管路清洁度实际情况。

Due to the test run, the new pipeline system is generally impurities, it is necessary to consider the new pump inlet to install a filter screen, the number of filter screen depends on the actual cleanliness of the pipeline.

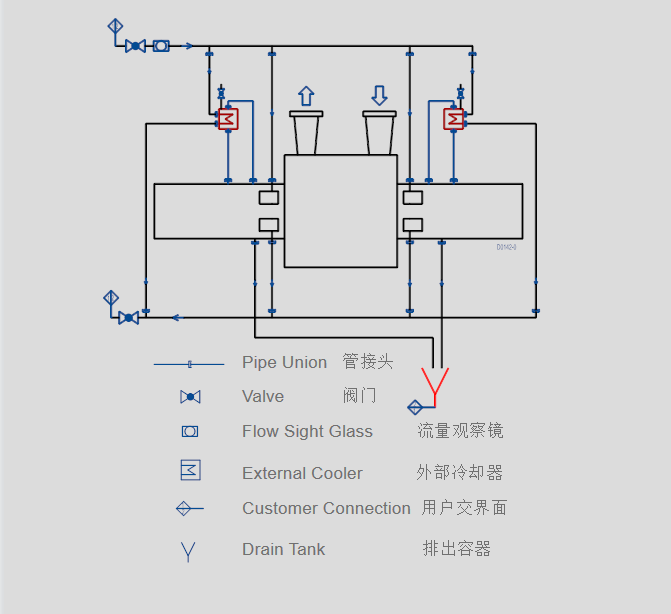

3,出口阀门关闭,小流量阀门打开。有些泵还配置冲洗方案,需要对照厂家资料,需要保证密封水系统按照设计正常运行。某些泵还配置轴承润滑油系统,需要确保润滑油系统正常运行-油量、油温、油速、油的洁净度在正常值。

Outlet valve closed, low flow valve open. Some pumps are also equippedwith a mechanical seal flushing scheme, which needs to be compared with the manufacturer's information to ensure that the sealed water system operates normally in accordance with the design. Some pumps are also equipped with bearing lubricating oil systems, which need to ensure the normal operation of the lubricating oil system - oil quantity, oil temperature, oil speed and oil cleanliness in normal values.

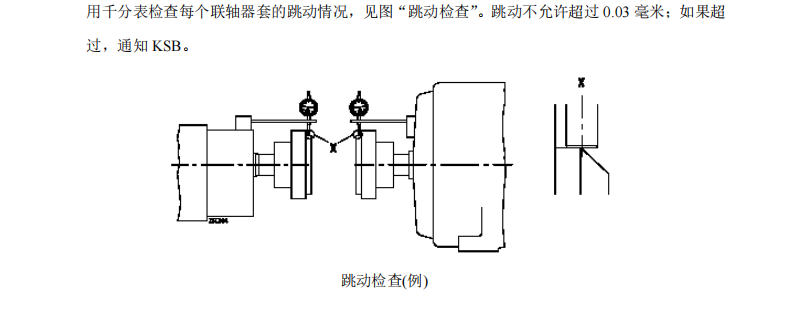

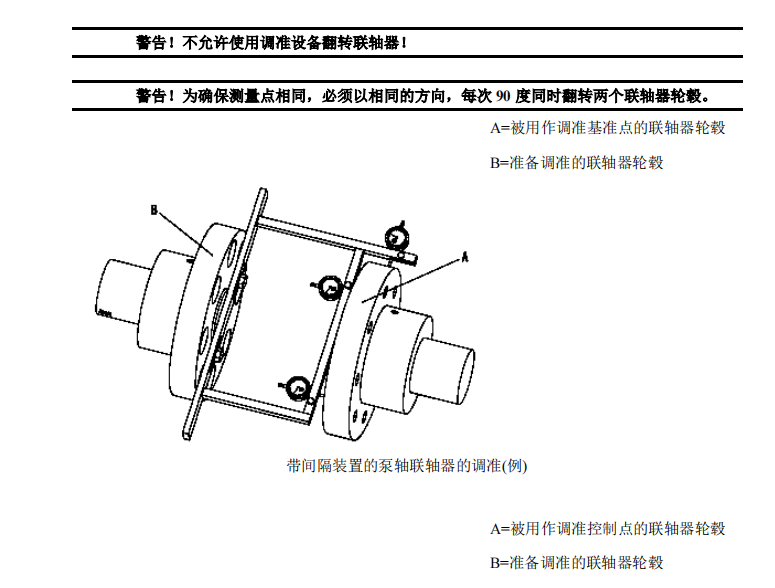

4,启泵前,需要点动确认电机转向与泵一致。水泵与电机已经完成对中,轴向与径向对中值满足要求,需要连接管路前检查对中情况,连接管路后再次检查对中,确保管路没有对泵产生过多的应力。如果驱动不是电机,某些大型给水泵是用小型汽轮机做功带动水泵运转,这种情况还需要对照汽轮机的热工作状态的偏差做补偿调整对中。

Before starting the pump, it is necessary to confirm that the motor steering is consistent with the pump. The water pump has been aligned with the motor, and the median of the axial and radial alignment meets the requirements. Check the alignment before connecting the pipeline, and check the alignment again after connecting the pipeline to ensure that the pipeline does not cause excessive stress on the pump. If the drive is not a motor, some large feed pumps use a small steam turbine to drive the water pump. In this case, the deviation of the thermal working state of the steam turbine needs to be compensated and adjusted.

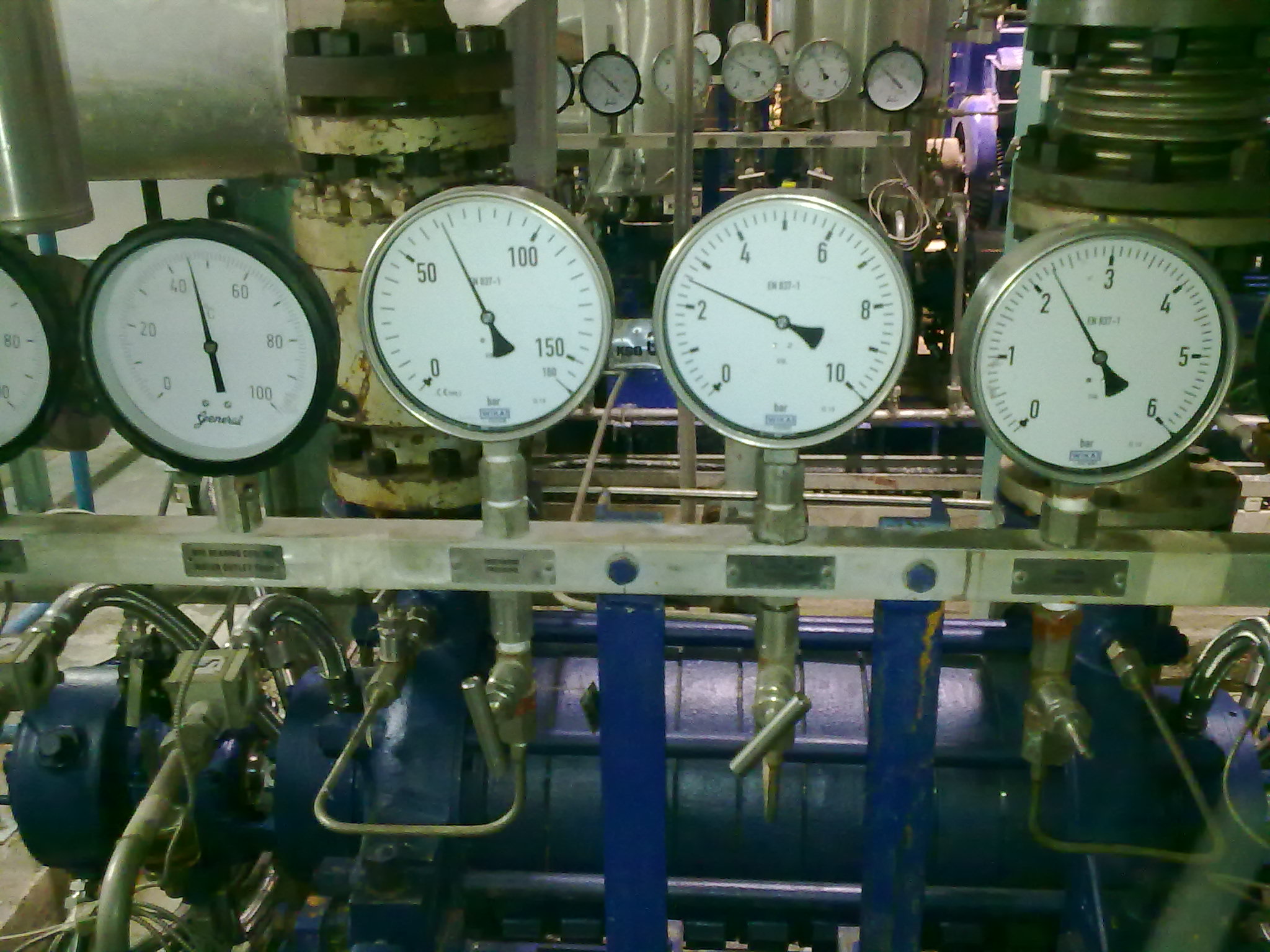

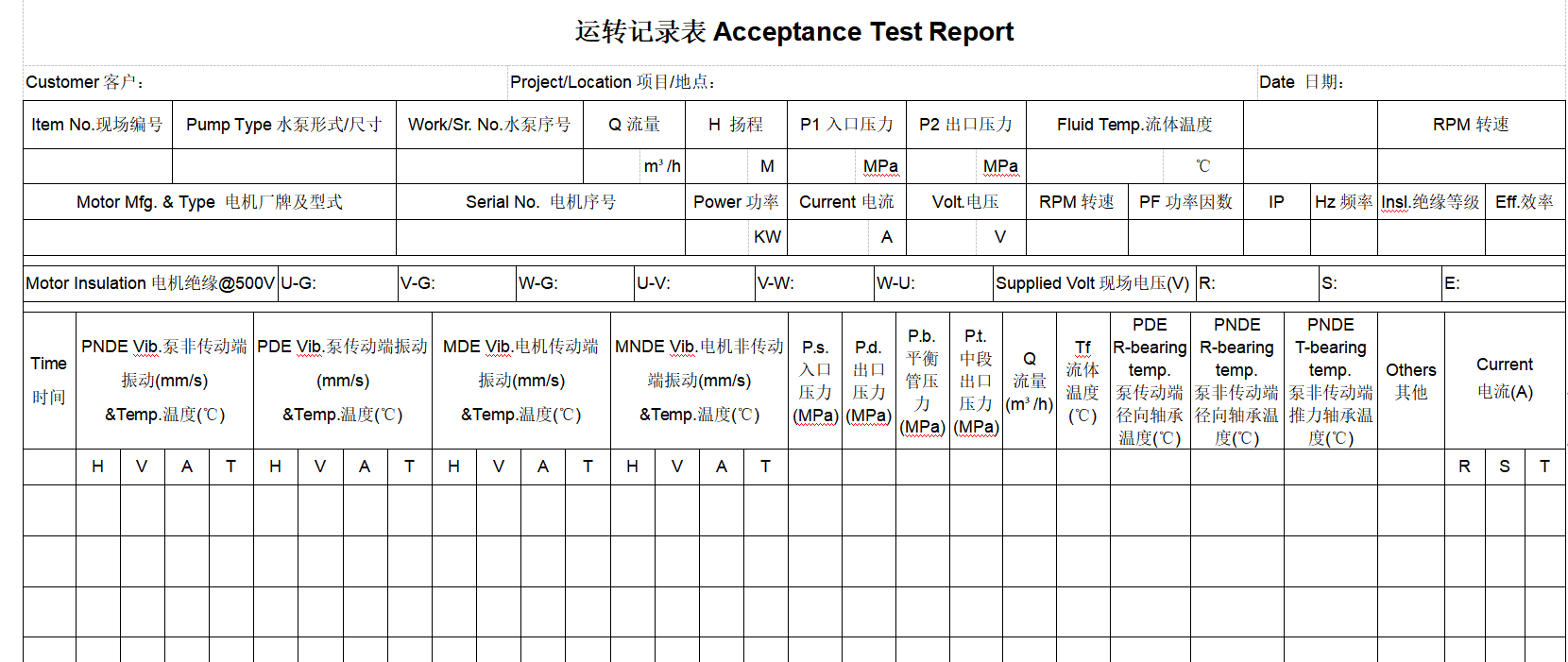

5,现场试泵,一般使用出口小流量管路,让泵在非工况点情况下运行,严苛的状态下检验泵的运行参数。流量,扬程(压力),电机电流,转速,水泵振动值(驱动端与非驱动端-水平、轴向、径向),电机振动值,噪音值,温度值等等。

Field test pump, generally use outlet small flow line, so that the pump in the case of non-working conditions, under the condition of strict test pump operating parameters. Flow RATE, HEAD (PRESSURE), MOTOR CURRENT, SPEED, PUMP VIBRATION (driven and NON-driven - horizontal, axial, radial), motor vibration, noise, temperature, etc.

6,试泵注意事项,对于多级高压离心泵,不能在出口没有背压的情况下,开启出口阀门启动泵,过高的轴向力会将整台泵瞬间报废。出口阀门关闭直到压力稳定后,慢慢开阀门到达工况点。好比饥饿的人不能一下子进补大餐一样。会出现消化系统紊乱。

Precautions for pump test: For multistage high-pressure centrifugal pump, it is not possible to open the outlet valve to start the pump without back pressure at the outlet. Too high axial force will scrap the whole pump instantly. Outlet valve closed until pressure stabilizes, slowly open valve to operating point. Just as a hungry person cannot eat a large meal at once. Digestive disorders can occur.

7,泵变频启动,时间不能太长或太短,启动时间长,会使泵出现咬死的情况发生。

Pump frequency conversion start, the time can not be too long or too short, long start time, the pump will be seized.